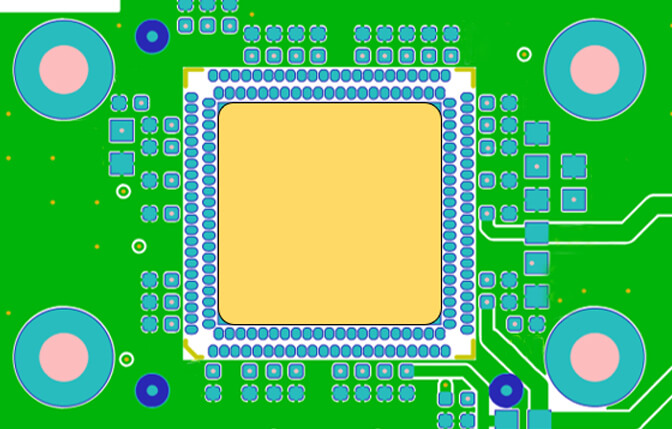

Enhanced Thermal Management with Copper Coin Technology from TCL

TCL is proud to offer Copper Coin technology - an advanced solution for superior thermal management in Printed Circuit Boards. Taking advantage of copper’s remarkable thermal conductivity of over 400 W/mK, Copper Coin technology effectively manages heat while maintaining excellent electrical performance.

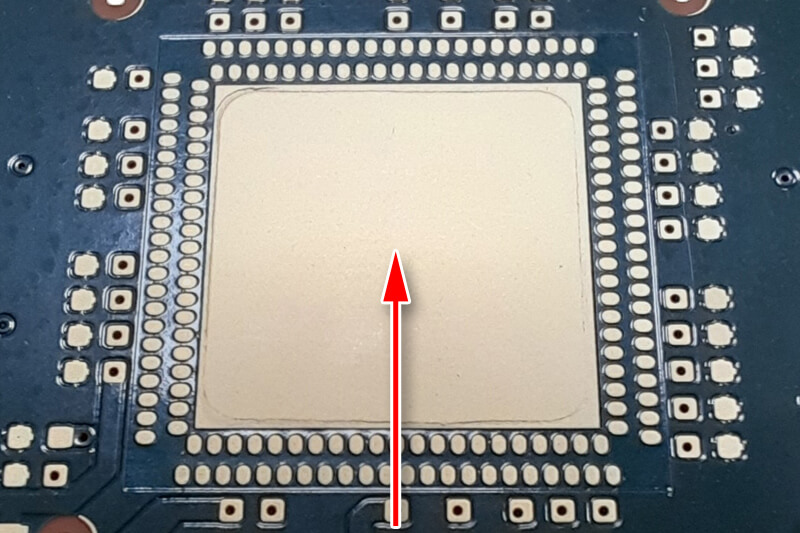

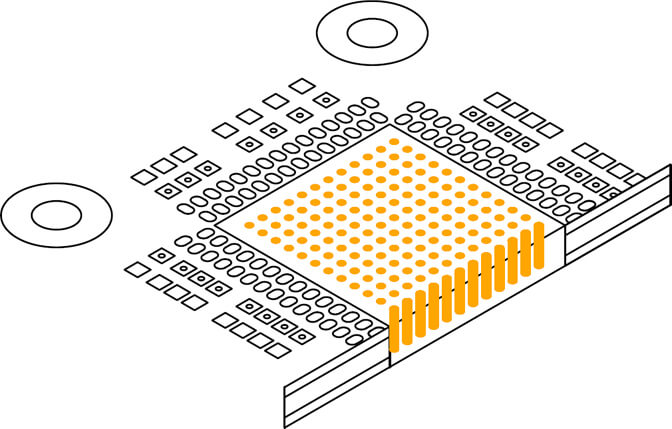

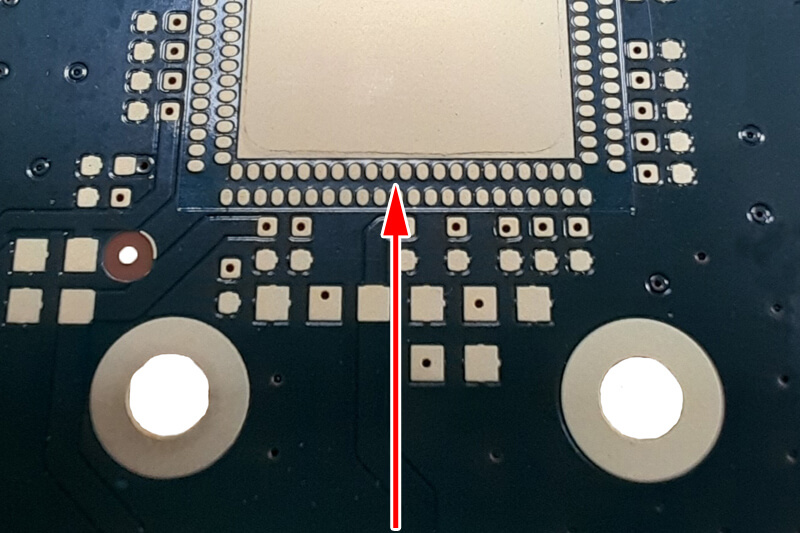

Solid Copper Coin

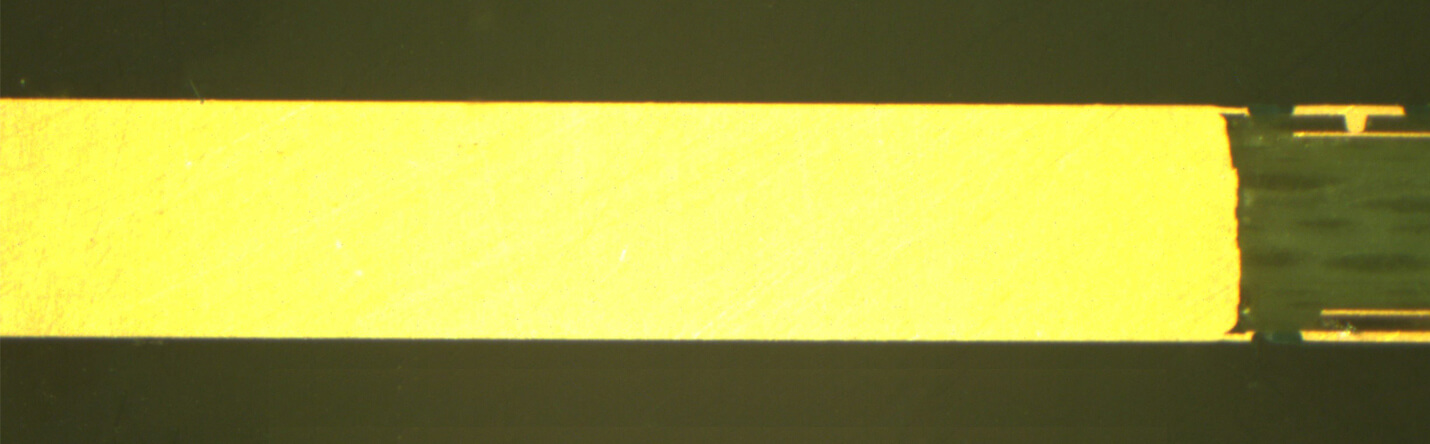

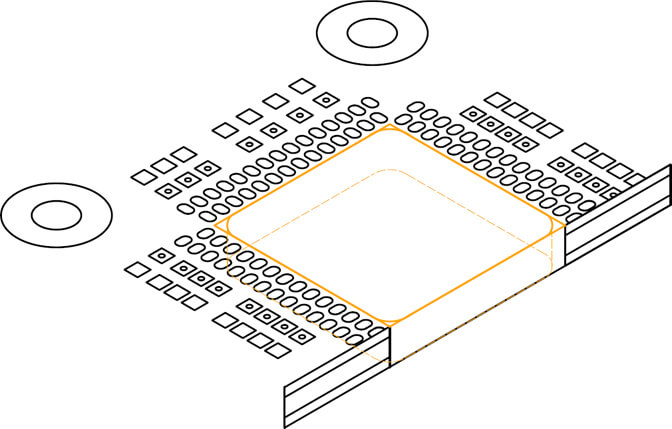

Solid Copper Coin Cross Section of Copper Coin

Cross Section of Copper CoinWhat is a Copper Coin?

A copper coin is a solid copper insert that is precisely placed within the PCB, typically beneath components that generate significant heat. This integration allows for direct heat transfer, significantly improving cooling performance. In fact, copper coins can deliver nearly double the cooling efficiency compared to standard thermal vias.

By providing direct contact between the heat source and the heat sink, copper coins eliminate the need for intermediate thermally conductive materials. This results in a thermal conductivity that is 50 to 200 times greater than traditional conductive dielectric materials.

Ideal for many applications

Copper Coin technology is particularly effective when heat is concentrated in specific areas of the PCB. Whether your design involves a single hot spot or a few high-temperature components, copper coins provide a localised heat management solution that works across any number of PCB layers.

TCL Circuits' Manufacturing Expertise

At TCL, we would manufacture Copper Coin PCBs using premium-grade C103 copper, renowned for its high electrical conductivity and resistance to hydrogen embrittlement. Depending on the design requirements, the copper coin can be embedded throughout the board or inserted from one side, providing effective heat dissipation for components above or below the coin.

Comprehensive Solutions for Complex Designs

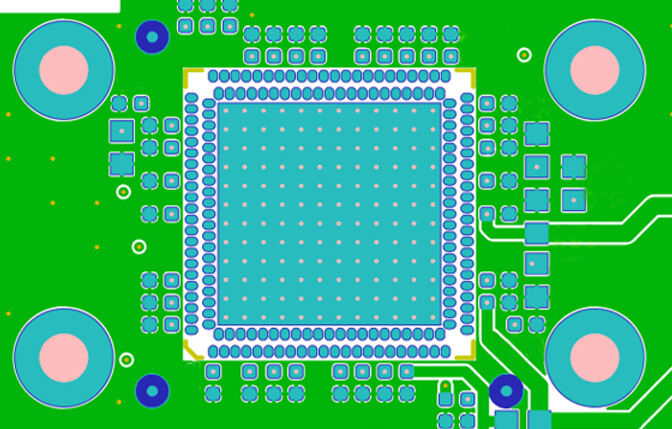

Our Copper Coin technology can be seamlessly integrated with other design solutions, such as copper-filled vias, to meet even the most challenging design requirements. By combining these technologies, we ensure optimal thermal management and electrical performance for your most demanding applications.

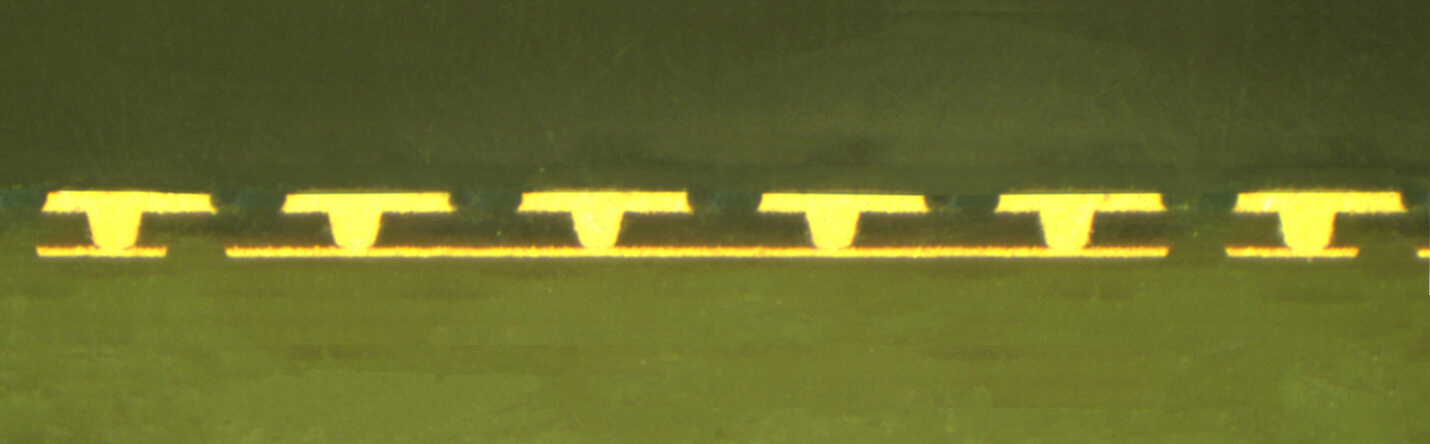

Copper filled blind vias

Copper filled blind vias Cross Section of Copper Filled Vias

Cross Section of Copper Filled Vias